INTERVIEW: Corinne Prevot of Skida on Cashmere

Skida's journey into cashmere and a look at the newest collection releasing today

Welcome to TOGS! Here we explore the culture of fashion in the outdoors, test clothing and gear, poke at trends, and bring you interesting stories like the one you’re about to read today.

We are a reader supported publication, so consider becoming a subscriber below to receive our all of our letters and support our work

Hello readers! Kellyn here. Today I’m speaking with Corinne Prevot, founder and CEO of Skida—

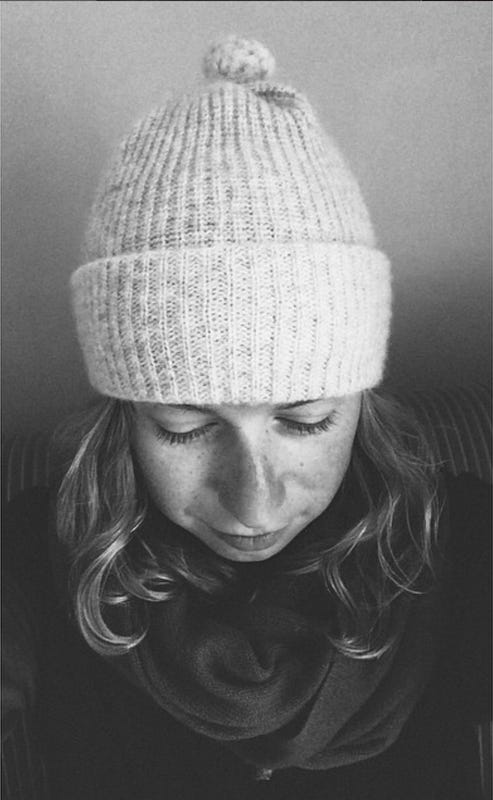

If you’ve spent any time in the mountains over the past decade, chances are you’ve crossed paths with a Skida hat. Maybe it was a bright, floral-printed cap on a Nordic skier’s noggin’, or a little fish pattern peeking out from under someone’s helmet at the ski hill. Wherever you spotted it, it most likely stuck out in a sea of earth tone alternatives. Skida’s founder Corinne Prevot started making those recognizable hats back in high school while racing for Burke Mountain Academy’s Nordic team. Since then, Skida has grown into nothing short of a mountain-town sensation. I remember my first Skida hat and the feminine super power boost it gave me in the mountains. (Photo at the bottom of the interview)

But there’s a whole cashmere collection at the brand that I know less about—

On the Skida website, a short note offers just a little peak into the story:

In 2011, Skida’s founder Corinne first discovered Nepal’s cashmere industry while living and studying in the Kathmandu Valley. From there, our collection of cashmere hats and scarves was born and has evolved over the last eleven years…

I wanted to know so much more. So I gave Corinne a ring. She answered from the Tetons, sitting in front of a log cabin wall. She has an easy, disarming smile—not that unlike her childhood photos you’ll see below—and a way of making conversation feel like chatting with an old friend. She always seems to have a heaping handful of projects in the works, and somehow manages to pull them all off with ease. We could have talked for hours, but I tried to stay focused on the topic at hand…

KW: Hi Corinne! Can you tell me a little bit about how Skida started and your background with textiles?

CP: I’ve always been kind of a textile nerd. Growing up, I was sewing, knitting, and crocheting—always making things. When I got into cross-country ski racing, my fleece hats just weren’t working…they were too hot. One time I took a hat off during a race and threw it aside, and when I went back to get it, it was gone. I was devastated, so I realized I needed to make something I could wear through a race without overheating. I took inspiration from cycling caps because they were using under-helmet materials that were lightweight and breathable.

Those fabrics typically came in swimwear prints, so they were very bright and colorful, florals—prints you wouldn’t necessarily put in a winter environment. That made that first batch really fun and vibrant. This is 2008, so we were still in a solid knit or striped knit era, a lot of itchy wools and acrylic blends. I paired the fabric with a microfleece on the inside for a warm-up hat. Those were the first styles in the line.

Another critical piece of information: I grew up on a sheep farm in south-central Pennsylvania, adjacent to Amish country. We raised sheep, my mom taught me about dyeing fibers, spinning yarn, and how mechanical processes differ from handcraft. I didn’t acknowledge how much of a foundation I had until I got to Nepal and realized I knew what questions to ask. I researched factories, talked to shop owners, and asked to see where things were made. Cashmere comes from goats, so I wanted to see the animals and the process. It was a shift realizing it wasn’t all done like our hobby farm back home.

KW: And how did you end up in Nepal and interested in cashmere?

CP: Fast forward four years, I was at Middlebury College and I really wanted to study abroad. I was at a turning point with ski racing where I knew I couldn’t do both. I decided to put athletics on pause. At Middlebury, to study abroad in a place that spoke a language, you needed a certain level of language credentials. My French wasn’t at a point where I could go to a French-speaking place, so my options were reduced to more obscure places. I landed on Nepal. I was excited about the mountains and inspired by the religions and really wanting to understand this totally different culture I knew nothing about.

Right before I left, my brother gave me a cashmere hat. (He has a great eye for textiles.) I knew cashmere was special, so when I went to Nepal for a study abroad program focused on international development and social change, I brought it with me. Part of the program included a 30-day independent research project. I was still learning about Nepal and trying to figure out what to focus on, but I noticed all the Pashmina shops in the Kathmandu Valley selling cashmere, often really cheap. I knew cashmere had a luxury reputation, so I wondered: How could it be sold so cheap? What was the difference between real and fake? I wanted to understand the fiber, where the real stuff came from, and why there was such a gap.

I started talking with factories, learning how they spun yarn, where they sourced fibers. At first, people were reluctant to let me in—it was like, “Why do you want to see this?” But eventually some doors opened.

KW: So through your research project, you were able to explore these factories and make connections?

CP: Exactly. I learned about how much of the fiber actually comes from Mongolia, China, and Tibet. In Nepal, it’s mostly imported raw material, then spun or woven there. The weaving heritage in Nepal is really strong—handlooms, jacquard looms, beautiful craftsmanship. That was fascinating to me.

It was such a contrast from what I grew up with—sheep on a farm, fleece spun by hand—to this large-scale industry. I started to see how much nuance there is in cashmere. Quality depends on the goat, the region, the grade of the fiber, and then how it’s spun and finished.

KW: What was the title of your project?

CP: (Laughing) I titled it “Pulling the Cash From Cashmere.”

KW: Oh now that’s catchy. Was there a language or cultural barrier at all?

CP: Actually one of the elements of the program that was so valuable was the language class. I got to a point with the language where I could conduct interviews with the factory workers. One of the factories I visited was run by a group of brothers—they call them “the uncles.” They paired me up with their nephew, Nitesh, who was just a couple years older than me. I was 19, he was maybe 23. He had grown up in the factory, so he showed me around, let me ask all my questions, and gave me the full rundown.

Fast forward to today and we still work with that same factory. Those uncles are starting to retire and now Nitesh is taking over. So it’s been this really beautiful relationship and such a rewarding element to the whole process.

CP: One of the things that really differentiates Nepal’s cashmere industry is the fact that historically, the fiber was brought down from the Himalayan plateau and all the fiber gets funneled down into Katmandu Valley. And usually it was done through traders, so you have these goat herders up in the mountains and then they’d sell the raw fiber to traders. Then they brush the fiber…

Corinne explained “brushing the fiber” to me: whereas sheep wool is shorn, goats get brushed. Cashmere comes from the underbelly fiber. It’s a bit like brushing a dog when they’re blowing their coat and you’re pulling out that fine, downy layer that sits beneath the outer guard hairs.

… and then they would load up these big bags and bring that fiber into Kathmandu Valley where they’d be hand spinning (before mechanized processes) just like what I was learning as a kid!

That’s how cashmere became this really luxurious thing. It was made by hand and goods, at this point, couldn’t be trucked across continents so that made them really valuable.

KW: How did things change once mechanization entered the picture?

CP: When textile processing techniques were mechanized, that’s when India and China really began developing factories and machines that could operate at much higher volumes and lower prices. It shifted cashmere into mass production.

Geographically, you also have to think about the Mongolian Plateau—that’s where most of the goats live. The fiber could be transported across the plateau into China, where so many textile factories were set up along the coast. That drove costs down and made cashmere much more accessible and widely produced.

For Nepal, that was a turning point. Their factories suddenly had to compete with this mass market. The ones that survived were those that maintained relationships with European retailers and rode out that wave. Those are the factories that are still around today. This was the focus of my project, “Pulling the Cash from Cashmere.”

KW: So fascinating. When you were there, were you already thinking about working cashmere into Skida?

CP: Not at all. At that time Skida was still just hats made in Vermont with my friends. Cashmere felt like this whole other world, but I was really intrigued. After my program ended, I kept going back to Nepal. Each trip I’d learn a little more, make a few more connections.

It wasn’t until a few years later that I thought, maybe there’s a way to bring this into the Skida line.

But, toward the end of my time there, I actually walked into the Sherpa store…you know, the brand? They had a big flagship in the Kathmandu Valley. By the time I left, I had placed some of our original (non-cashmere) Skida products in that store, which was such a cool connection point.

KW: You just walked in and asked if they’d sell your hats?

CP: Yeah! I brought in some pieces I had made in the U.S. and told them, “These are perfect for trekking.” And they were psyched. They entertained it, and that turned into a really fun relationship. I’m still friends with the founders!

KW: Ok so when did the idea of actually bringing in cashmere start?

CP: It was a slow build. After that first exposure in college, I kept returning to Nepal. Each time, I’d visit some of the same weaving houses, check in with people I’d met, learn more about what made certain scarves softer or stronger, and slowly form relationships.

Skida, at that point, was still so Vermont-based. It wasn’t until maybe 2015 or 2016 that I thought: what if we added something totally different, but still textile focused, to the line?

It felt aligned because our brand has always been about headwear and scarves. So when I thought about introducing cashmere, it wasn’t a stretch.

KW: How did you begin producing?

CP: At first, small. Really small. I brought home a handful of samples—just a few scarves from one of the weavers I’d gotten close to. I shared them with friends, wore them myself. It was like, “Okay, this is resonating. There’s something here.”

From there, I worked with that weaving house to develop a few colorways just for Skida. That was the first time it became a real product in our line.

I immediately felt supporting the Nepali manufacturing was what was important. And it wasn’t that dissimilar to what we were already doing in Vermont! Our fabrics get printed in California. We bring them to Vermont where we are cutting and sewing. Similarly with cashmere, they’re bring in raw materials from a place they know the quality is reliable, and then bringing them back to them and knitting or weaving them locally.

KW: How was that first collection received?

CP: We debuted at the Burlington Art Hop! People were excited—it was new and different. We’ve had some loyal cashmere customers since then. Because of our relationship with the factories, we don’t really have minimums. We can make one-offs, experiment with more colors, and sample a lot before producing.

KW: Do you have any new cashmere pieces coming this year?

CP: For fall/winter, we’re releasing two Fair Isle sweaters…

KW: Ah!!!

Here’s a peek at the cashmere collection coming out today! (September 25th)

KW: This is so exciting, and knowing the full story behind the cashmere makes the collection feel even more meaningful. And that it comes from a good and sustainable source.!

CP: That’s exactly it. This program definitely has a sustainability element, but I always want to acknowledge—it’s not perfect. But we’re not mass-producing, and we’re learning more every year about the industry. Nothing is ever really entirely sustainable. What’s most important is staying connected to our Nepal-based makers and community.

Kellyn: That honesty is refreshing.

Corinne: It’s most sustainable to buy something once and use it for ten years—that’s what matters. I still wear cashmere hats we made a decade ago. They hold up, they’re versatile, and that kind of utility feels so important.

Thank you so much to Corinne and the lovely team at Skida for helping facilitate this interview and give TOGS readers a first look at the cashmere collection. We love supporting brands like Skida and sharing the stories behind their work.

As promised: me and my very first Skida hat, unleashing all the feminine power I imagined it would bring.

Thanks for reading,

Kellyn

When my mom passed I ended up taking a small drawer in her bedroom dresser for my Skidas. Now I have that small drawer plus two big ones (and my mom's best things, of course!) Every time I grab a Skida I think of my mom. My husband walked in last winter when a drawer was open and said, "I didn't realize you had so many Skidas." I 'forgot' to show him the other drawers... Thanks for this interview. Janise

Skida hats are the best! I use mine all the time skiing in the Wood River Valley! Can’t wait to try a cashmere anything!